Incentives for Your Business

Prescriptive Lighting

Earn An Incentive

while improving lighting quality and environmental benefits

Lighting technologies developed in the past twenty years can help cut your lighting costs up to 90 percent while enhancing lighting quality and reducing environmental impacts.

Your utility’s Commercial/Industrial Lighting Efficiency Program offers cash incentives to help cover the cost of a variety of energy-efficient upgrades.

| Existing Lighting | Eligible Products | New LED Wattage | Incentive ($5/Unit) |

|---|---|---|---|

Linear Fluorescent Fixtures (Includes fixtures using 2 ft. U-bend tubes) | NEW Solid-State LED Fixtures | 9 – 22 watts LED | $5 |

| 23 – 45 watts LED | $10 | ||

| 46 – 68 watts LED | $15 | ||

| 69 watts or greater | $20 | ||

| Retrofits - LED Tube Lamps - LED Panels - LED Retrofit Kits | 9 – 22 watts LED | $2 | |

| 23 – 45 watts LED | $4 | ||

| 46 – 68 watts LED | $6 | ||

| 69 watts | $8 | ||

High Bay or Exterior Dusk-to-Dawn Fixtures: — Mercury Vapor — High Pressure Sodium — Metal Halide — Incandescent (300 watts or greater) (Must have large mogul-base) | NEW Solid-State LED Fixtures | 9 – 65 watts | $20 |

| 66 – 130 watts | $40 | ||

| 131 – 240 watts | $60 | ||

| 241 watts or greater | $80 | ||

| Retrofits - LED retrofit lamps - LED retrofit kits | 9 – 65 watts | $8 | |

| 66 – 130 watts | $16 | ||

| 131 – 240 watts | $24 | ||

| 241 watts or greater | $32 | ||

| Incandescent Exit Sign | Solid-State LED Exit Sign | 8 watts or less | $10 |

| Fluorescent refrigerated case lighting | 5' or 6' LED Tube Lamps | $20 | |

| Switched controls only | Occupancy Sensor | $15 |

Guidelines

- Existing facilities only. New construction does not qualify.

- All equipment must be permanently installed.

- All solid-state fixtures, retrofit lamps, tubes and kits must be standard or premium-listed by the DesignLights Consortium (view designlights.org for more details).

- Upgrades to recessed can lights, down lights, fluorescent fixtures less than three (3) foot of linear length and existing LED lighting do not qualify.

- Projects for incentives of $5,000 or greater require pre-approval.

- After installation is complete, applications, along with sales receipt(s) or invoice(s) itemizing the make, model and input wattage, can be submitted to the electric utility for processing.

- All incentives are subject to the terms and conditions as outlined in the application and the General Guidelines.

Additional Information

Commercial HVAC

Earn An Incentive

when installing a qualified Commercial HVAC unit

HVAC systems are the primary energy consumers in commercial buildings. Improving the performance of your HVAC system not only saves energy, but can have a positive impact on your building occupants´ health, comfort, and productivity as well.

Eligible Equipment

| Unit Code | Equipment Type (Split or Package) | Incentive Criteria (SEER Ratings) | Incentive Criteria (SEER2 Ratings) | Incentive |

|---|---|---|---|---|

| AC1 | Air Conditioner | 16+ SEER or 15.8+ IEER | 15.2+ SEER2 or 15.8+ IEER | $30/ton |

| AC2 | Air Conditioner – Variable Capacity* | n/a | n/a | $60/ton |

| AS1 | Air Source Heat Pump | 15-15.9 SEER, 8.5 HSPF or 14.1-15 IEER, 3.4 COP | 14.3-15.1 SEER2, 7.5 HSPF2 or 14.1-15 IEER, 3.4 COP | $60/ton |

| AS2 | Air Source Heat Pump | 16+ SEER, 8.5 HSPF or 15.1+ IEER, 3.4 COP | 15.2+ SEER2, 7.5 HSPF2 or 15.1+ IEER, 3.4 COP | $120/ton |

| AS3 | Air Source Heat Pump – Variable Capacity* | n/a | n/a | $150/ton |

| WLHP | Water Source Heat Pump** | n/a | n/a | $150/ton |

| GHP | Geothermal Heat Pump** | n/a | n/a | $330/ton |

* Provide documentation that shows manufacturer, model number and that states the equipment is “inverter driven”.

** Any efficiency rating qualifies on water-to-air and water-to-water units.

WLHP — Water Source Heat Pump (typically boiler/cooling tower applications); GHP — Geothermal Heat Pump (open loop, earth, or pond coupled)

Table implies new matched indoor and outdoor components. If different, contact your electric utility

Equipment efficiencies are full load ratings according to test procedures and conditions specified in ASHRAE Standard 90.1 – Energy Standard for Building Except Low-Rise Residential Buildings, and the following standards as applicable: AHRI/ISO 13256-1 – Water-to-Air and Brine-to-Air Heat Pumps, AHRI/ISO 13256-2 – Water-to-Water and Brine-to-Water Heat Pumps, and ANSI/AHRI Standard 1230 – Performance Rating of Variable Refrigerant Flow Multi-Split Air-Conditioning and Heat Pump Equipment. COP ratings are at 47°F.

Guidelines

- All HVAC equipment must be new and permanently installed in new or existing nonresidential or master-metered multifamily buildings.

- Qualifying equipment must meet both cooling and heating (if applicable) efficiency levels as shown in the table and must be rated at the most recent AHRI standards. Water source, open loop, and closed loop ground source heat pumps can be water-to-air heat pumps or water-to-water heat pumps.

- An incentive payment will be paid to the customer after the equipment is installed, operational, and with the following completed: air and water balancing, installation and calibration of control system, and training of customer’s maintenance personnel.

- Indoor and outdoor components must be matched.

- Incentives greater than $5,000 must be pre-approved by the local electric utility to guarantee availability of funds.

- Program is subject to the Terms and Conditions as outlined on the application and the General Guidelines.

Additional Information

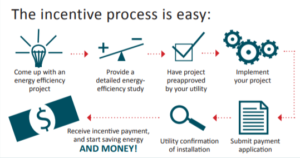

Industrial Process

Earn An Incentive

when you improve production through our industrial process incentive

In an industrial plant, energy efficiency improvement projects often are unique and do not fit a prescriptive program. Each manufacturing plant has certain characteristics that can require an individual approach to projects.

All projects must be preapproved before any equipment is ordered. In addition, the customer is required to document potential project energy savings by providing a detailed study. Incentives are paid based on annual savings versus baseline usage and payback criteria. After a project is preapproved, an estimated incentive is calculated and equipment can be ordered and installed. After installation, an incentive payment application is submitted for payment along with verification and documentation of the original project assumptions.

Examples of possible industrial energy efficiency projects include:

- Variable frequency drives for injection molding

- Compressed air efficiency improvements

- More efficient curing

- Refrigeration improvements

- Improved process chiller operation

- Welding process improvements

Also included are projects that improve production without increasing energy consumption.

Guidelines

- Available to industrial and large commercial customers.

- Incentives are not available for Energy Conservation Measures (ECMs) that qualify for other incentive programs.

- Customer must provide a complete description of existing process and the proposed changes along with an explanation of how energy savings will be achieved. In addition, customer must provide an initial detailed calculation of estimated energy savings. This calculation may be performed by either a consulting engineer, a competent vendor, or the customer’s internal support staff.

- Preappoval application must be completed and preapproved to receive an incentive.

- All incentives require approval by the electric utility before purchase or installation.

- To obtain incentive, an Incentive Payment Application must be completed and proof of purchase that itemizes the new equipment indicating the type, make, model, size, and purchase date must be provided. In no case will the incentive be more than 50% of the invoiced project cost. Projects with a two year or less simple payback are ineligible.

- Program is subject to the Terms and Conditions as outlined on the application and the EnergyWise℠ General Guidelines for all Programs.

- Changes must be implemented and submitted for payment within one year of the preapproval.

Additional Information

Variable Frequency Drive

Earn An Incentive

when you reduce power and energy consumption

Variable frequency drives (VFDs, also referred to as variable speed drives) can reduce output by controlling the motor rather than having the motor work at a constant, almost full load and adjusting the system to obtain a desired result. Variable speed drives are especially effective at reducing power and energy consumption to centrifugal equipment such as pumps and fans. This is because a reduction in flow is directly proportional to a reduction in speed, while the reduction in power is proportional to the cube of the change in speed.

Potential Savings

For centrifugal loads, small decreases in equipment rotating speed or fluid flow yield significant reductions in energy use. For example, reducing speed (flow) by 20 percent can reduce power requirements by approximately 50 percent. (See Energy Saving Chart, below)

VFD Energy Saving Chart

| Load | Savings |

|---|---|

| 100% | 0% |

| 90% | 27.1% |

| 80% | 48.8% |

| 70% | 65.7% |

| 60% | 78.4% |

| Centrifugal loads only. Actual savings will vary based on load and motor characteristics. | |

Guidelines

- Available to industrial and large commercial customers.

- The completed application must be accompanied by proof of purchase that itemizes the new equipment indicating the type, make, model, size, and purchase date.

- Program is limited to drives from 1 to 200 horsepower.

- The equipment must operate at a minimum of 2000 hours annually.

- Incentives will not be offered to replace existing VFDs or for single phase service. The system controlled must have significant load diversity that will result in savings through motor speed variation. VFD speed must be automatically controlled. VFD must control centrifugal fans or pumps. New construction HVAC pumps and fans are ineligible. It is highly recommended to install protective equipment to maintain VFD reliability.

- Incentives exceeding $5,000 require approval by the electric utility before purchase or installation.

- Program is subject to the Terms and Conditions as outlined on the application and to the General Guidelines.

Additional Information

Custom Lighting

Earn An Incentive

when enhancing lighting quality

If your proposed LED lighting improvements are not available under the Prescriptive Lighting Incentive program, the Custom Lighting Incentive program may apply.

Guidelines

- All replaced or retrofitted lighting equipment must be permanently installed.

- Only lighting systems in existing facilities qualify for the upgrade. Existing premises have previously received permanent, electrical service for twelve (12) months or more.

- New construction or the facility additions do not qualify.

- All custom incentive projects must be pre-approved by an Energy Efficiency Consultant from Nebraska Public Power District (NPPD) prior to the removal of any existing lighting equipment (Energy Efficiency Consultant contact information listed at end of document). The Energy Efficiency Consultant will calculate the anticipated incentive to meet the lesser amount of the following criteria:

— Annual kWh energy savings x $0.07 per kWh

— 50% of associated costs to complete installation - The NPPD Energy Efficiency Consultant must sign the application form and return it to the customer and/or electric utility. Utility personnel must perform a visual verification of equipment at the conclusion of the installation and confirm the documentation provided by the NPPD Energy Efficiency Consultant. In the event variances in the newly installed equipment occurs, (i.e., description, quantity, wattage, operating hours) utility personnel will contact the original supporting Energy Efficiency Consultant so that modifications to the original calculations can be completed and a revised incentive can be determined.

- An incentive will be provided to the person responsible for the utility account after the equipment is installed and operating. The application form must then be signed by the owner and installing contractor (contractor signature may be waived if pre-printed receipt(s) and/or invoices clearly indicate professional installation). ALL CUSTOM INCENTIVES MUST BE APPROVED BY AN NPPD ENERGY EFFICIENCY CONSULTANT PRIOR TO ANY REMOVAL OF THE CURRENT SYSTEM. After the proposed system installation is completed and operational, the completed application form will then be submitted to the electric utility for processing. Sales receipt(s) or invoice(s) itemizing the new equipment and indicating the size, input wattage type, make, model, purchase date, and vendor must accompany each energy efficiency incentive application.

- All lighting incentives require upgrading to light-emitting diode (LED) technology.

- Application to Custom Lighting Incentive program cannot be made if the proposed lighting improvements are available under the Prescriptive Lighting Incentive program.

- The incentive payment or account credit to the owner will come directly from their local electric utility.

- NPPD reserves the right to do random spot checks of the performance verifications to ensure program compliance.

- Participating electric utilities are wholesale customers of Nebraska Public Power District.

- NPPD will make final determination of program compliance decisions and reserves the right to cancel the program with 30 days’ notice.

- The prescriptive and custom lighting efficiency programs cannot be used in conjunction for the same fixtures with the exception for the installation of occupancy sensors.

- In the event the customer utilizes in-house electrician(s) or staff to complete the lighting efficiency improvements under the custom lighting efficiency program, this program will recognize the following expenses in calculating the cost of installation:

— Retrofits – $30 per fixture

— Fixture replacements – $50 per fixture

— Screw or plug-in LED replacement lamps – $0 - Existing lighting system equipment must be removed or decommissioned and rendered permanently inoperable to the satisfaction of the NPPD Energy Efficiency Consultant.

- Technical Specifications of all proposed lighting fixtures must be provided prior to pre-approval.

- Schematic layouts of proposed lighting upgrades with foot-candles identified must be provided before pre-approval can be provided.

- Proposed lighting levels must be within 20% of the Illuminating Engineering Society of North America’s recommendations for like spaces.

Additional Information

HVAC System Optimization

Earn An Incentive

when optimizing your building’s HVAC system

The purpose of this program is to improve the efficiency of existing commercial building HVAC systems. Examples of optimization improvements include: converting constant volume pumping or air-handling systems to variable flow; improving control schemes of chiller, boiler, air-handling and pumping systems; installing economizers or improving their control schemes, etc. It does not apply to new construction. This program completely stands alone and may not be used in conjunction with any other incentive programs.

Typical benefits of optimizing your HVAC system

- Reduced energy usage and costs

- Improved occupant comfort

- Better trained and educated in-house maintenance staff to operate the HVAC system

- Documentation of changes for future reference

Guidelines

- An evaluation of the Customer’s HVAC system(s) is completed by an HVAC expert (contractor, dealer, engineering consultant). The evaluation should contain a description of Energy Efficiency Improvements (Improvements), energy and demand savings (both electric and fossil fuel), and cost to implement Improvements. Two years of utility billing history (electricity energy and demand, and fossil fuel therms or gallons) is to be included.

- Customer submits a completed HVAC System Optimization Application (Application) to local electric utility.

- Electric utility provides incentive amounts on the Application and sends back to Customer. This step is considered approval from the electric utility for equipment to be ordered/installed.

- Customer implements Improvements of their choosing. Upon completion of installation of the Improvements, Customer forwards the Application, invoices of equipment and material installed, and W-9 for electric utility review.

- All Improvements should be permanently installed within twelve (12) months of the date of utility representative’s signature on the Application.

- The HVAC expert provides training for building staff on how to operate the HVAC system efficiently, and provides all project documentation to Customer.

- An electric utility representative performs visual verification of equipment after completion of installation.

- Electric utility makes payment of the incentives to the Customer.

- If desired, a case study may be created by Customer and/or HVAC expert to showcase energy savings of the project.

- Program is subject to the Terms and Conditions as outlined on the application and to the General Guidelines.

Additional Information

Heat Pump Water Heater

Earn An Incentive

when you install a heat pump water heater

Heat pump water heaters offer improved efficiency and increased energy savings compared to standard units. The benefit of a heat pump water heater is that you get at least twice as much hot water from each kilowatt-hour of electricity consumed as you get from a standard electric water heater. And, while a heat pump water system costs more upfront, the savings will pay back the difference in two years for a household of four.

| System Type | Incentive Criteria | Incentive Amount |

|---|---|---|

| Air Source HP Water Heater | EF > 1.9 | $400 |

| Water or Ground Source HP Water Heater | COP > 2.8 | $650 |

Guidelines

The following guidelines will generally apply. Exceptions will be handled on a case-by-case

basis.

- All heat pump water heaters must be permanently installed.

- An incentive payment will be paid to the owner after the equipment is installed, operating, and tested by the installer to manufacture recommendations. No incentive(s) will be paid without the completion of the application form. The application form must then be signed by both the installer and the owner. This form will then be submitted to the owner’s electric utility.

- The incentive payment to the owner will come directly from their local electric utility.

- Low Interest Loan – For homeowners who choose this option the program is administered through the Nebraska Energy Offices – Dollar and Energy Savings Loan Program. For more information go to http://www.neo.ne.gov.

- Program is subject to the Terms and Conditions as outlined on the application and to the General Guidelines.